4800 Meadows Rd Suite 346 Lake Oswego OR 97035 – in person inquiry by appointment only

ZERO CLEARANCE FIREPLACE CLEANING

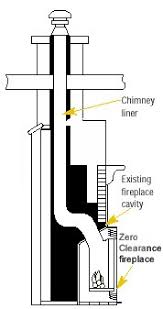

Zero Clearance Fireplaces often referred to as prefabricated fireplaces, are factory-built units constructed from materials like sheet metal or cast iron. They are designed for easy installation and come complete with assembly instructions and framework requirements. These fireplaces are commonly used by professional builders and are prevalent in apartment and condominium complexes, as well as newer homes constructed from the mid to late 1980s onward.

The term “zero clearance” signifies that these fireplaces are well-insulated, allowing them to be safely installed in close proximity to combustible materials like walls or wood framework, without the need for a traditional masonry foundation. Zero clearance fireplaces may vary in features, with some equipped with glass doors and others featuring spark arrester screens.

ZERO CLEARANCE FIREPLACE LINER FLUE

The flue is the passage in your fireplace responsible for allowing smoke to rise up and exit. The dimensions of your flue, as well as every component of your zero-clearance fireplace, are based on carefully coordinated measurements. As smoke ascends through your flue, it adheres to the flue walls as soot, gradually obstructing the flue’s interior.

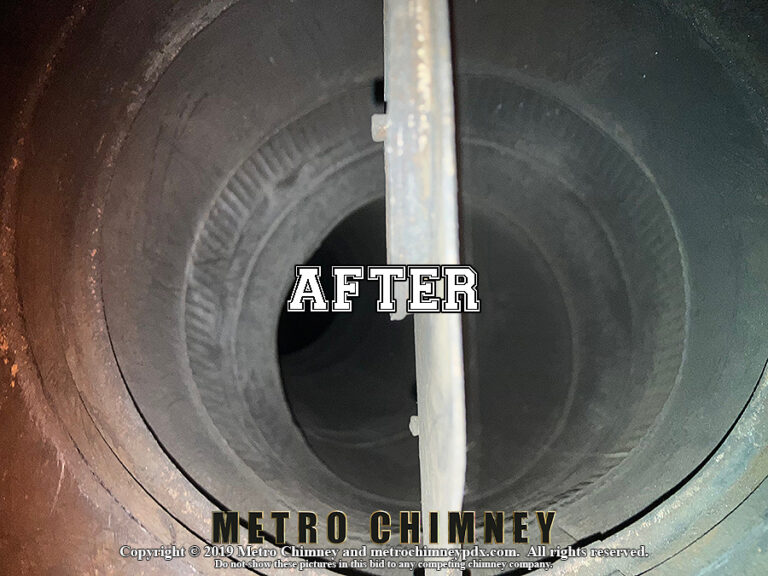

Since the flue of a Zero Clearance Fireplace is usually an 12 to 16 inch round liner pipe (as depicted in the picture below) that runs up the interior of wooden or brick enclosures, it tends to accumulate soot and close down more rapidly than a masonry fireplace during use. Solid particles burn as carbon, commonly known as soot, and can accumulate, diminishing the interior dimensions of your flue, rendering it less effective. More significantly, creosote is an unavoidable by-product of burning wood, forming when wood smoke condenses on the inside of a cool chimney. Zero Clearance fireplaces should undergo annual cleaning if used.

If creosote is left unattended and allowed to accumulate over time, it can superheat and transform into 3rd degree creosote. (The picture below illustrates 3rd Degree Creosote in a masonry flue and is provided as a visual example.)

If creosote is left unattended and allowed to accumulate over time, it can superheat and transform into 3rd degree creosote. (The picture below illustrates 3rd Degree Creosote in a masonry flue and is provided as a visual example.)

This is the leading cause of chimney fires. Therefore, having our Chimney Sweeps come out to perform a chimney cleaning not only restores your flue’s interior dimensions to its proper working size but, if done early enough, can prevent creosote buildup that might become unremovable with a regular sweep, requiring additional actions to ensure the safety of your chimney. The advantage of Zero Clearance Fireplace liners is that they are made of metal, making it difficult for creosote to accumulate permanently, unlike masonry fireplaces, which are constructed from porous bricks. Cleaning them annually will effectively address any creosote issues your unit may have.

When we clean a zero-clearance fireplace flue, we ensure the removal of both soot and creosote from the fireplace pipe. If they are heavily used and have enough of a level of 2nd or 3rd stage creosote we will direct you to get a certain anti creosote spray and instruct you on how to use it to take care of that. Chimney sweeps can only knock off soot and First Stage Creosote with our brushes. Second Stage Creosote is tar and Third Stage Creosote is varnish and they will embed themselves into the pores or pits created by soot being on the metal for a long time of a used liner and the spray we are recommend will change them into a fluffy substance that is no longer flammable or acidic, will not cling to the liner and will either fall off on it’s own or during the next chimney cleaning. If the 2nd stage or 3rd stage creosote level is bad enough, we will put you on a detailed burning regimen using the Anti Creosote spray to get rid of it as much as possible. Also do not use those Anti Creosote Logs you see sold in stores in the winter time. They do not work. We have also tried the many expensive one time creosote cleaning products that other companies are offering and we have found they do not work either. The spray is the best of the Anti Creosote Sprays available, and it is the only one that really works but it does over a period of time every time you use your fireplace.

It is equally important to periodically clean a Zero Clearance Fireplace to prevent the buildup of soot from corroding the interior metal of the flue or causing rust. Carbon, when left unchecked, can corrode materials on a molecular level. To extend the lifespan of your flue, especially if you use your wood stove frequently, it is advisable to have it cleaned annually. This maintenance routine can help you avoid the need for costly flue replacement down the line.

During your zero clearance fireplace cleaning, we conduct a thorough examination of your system to provide you with a Safety Inspection Report detailing the condition of your zero clearance fireplace unit. This inspection includes identifying any problem areas and making repair recommendations, all of which are documented on your receipt. We also assess the installation to ensure there are no hazards resulting from improper setup and verify the functionality of essential components such as the damper and clay refractory heat deflection panels.

If any repairs are needed, we will outline them in the inspection report so that you can promptly reach out to the manufacturer or an authorized replacement part supplier to obtain the correct replacement components.

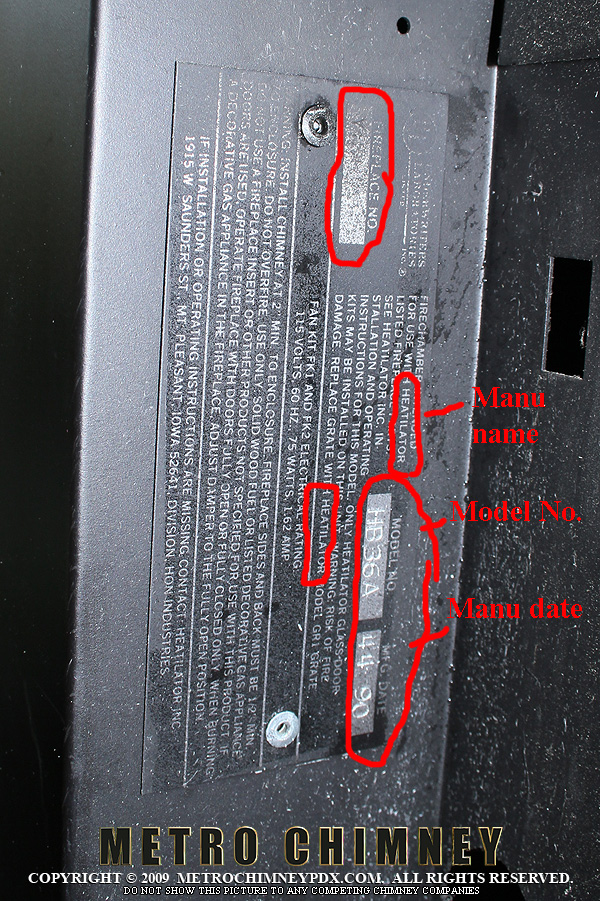

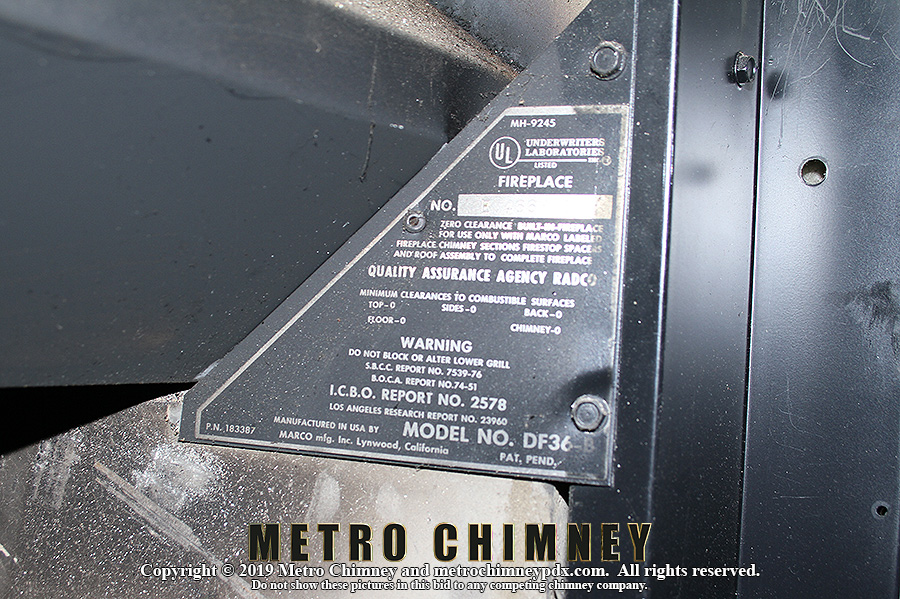

It’s worth noting that each new model of Zero Clearance Fireplace must undergo testing by United Laboratories (U.L.) for approval. Once these units pass U.L. testing and receive clearance for mass production, they are equipped with a placard that includes information such as the manufacturer, model number, serial number, and date of manufacture. This placard is affixed to the front of the unit, and its appearance may vary, but it typically resembles the example picture provided. Below are two examples of UL plate styles found on the front opening area of a zero clearance fireplace.

Before a new Zero Clearance Model can be mass produced and go up for sale to the public in the US the Manufacturer has to send the Unit’s kit to undergo testing at United Laboratories (UL) for safety compliance and for the Insurance Underwriting for the Model Number and everything that is sold with it (including the unit itself, the liner, damper, cap, storm collar, chase cover and all integral components) as well as and and all replacement parts and any optional parts for that make and model number. If a part within the unit has malfunctioned or is broken, it must be replaced with the Original Manufacturer’s Replacement Part for that Make and Model Number (if available) to maintain UL (United Laboratories) certification and comply with the insurance requirements. Replacement of any parts with aftermarket parts, even if the part itself went through UL testing, is now no longer allowed. Only the official replacement parts for that make and model number that were tested with the unit when it was originally tested by UL are allowed. If they are no longer available you can not put on a aftermarket part any more. If anything happens to the unit and it is discovered by the investigator that an aftermarket part was installed on it will nullify the insurance coverage for loss of life or property damage due to the unit.

I had this come up recently with a customer wh0 had a Canadian version of a Zero Clearance Fireplace installed in his home that he bought in Oregon 20 years ago from a local wood stove sore who also installed it. Only Zero Clearance Fireplaces made for the US Market and which has gone through UL testing and has a UL Placard on it can be installed in homes in the US. A Canadian model that has gone through their own version of UL can not be installed in the US as that was tested in Canada and the insurance only covers it if it is installed in Canada. This includes any model of Zero Clearance Fireplace or wood stove manufactured in another country that is not the US model of that unit and does not have a UL plate on it is an illegal fireplace in the US. If anything happens because of the unit Insurance will not cover the loss of life or property damage as that unit is installed in a country that it is not meant for or tested for.

If the entire unit (unit, liner, et all) needs replacing, You will need to contact the local rep for one of the Zero Clearance Fireplace Manufacturers. They will have a Licensed Wood Stove Installer Install the new unit for you. Chimney sweeps can no longer replace these units anymore in Oregon.

Please be aware that if the installer forgot to install the UL placard, or it was installed but now gone, there is no way to tell what the make and model of the unit is. Even if we know the year it was installed each manufacturer made 10 or more different units that share similar design appearances by eye but are completely different model numbers and only the UL plate tells you which model number it is. Also many manufacturers shared the same design looks and trying to determine what make it is is not possible without the plate as well.

FIREPLACE AND CHIMNEY SAFETY INSPECTION

During your chimney cleaning, we conduct a comprehensive assessment of your entire system, providing you with a Safety Inspection Report detailing the condition of your fireplace and chimney. Any identified problem areas and recommended repairs will be documented on this inspection report, which is also included as part of your receipt. If any repairs are deemed necessary, we will send you an estimate for the chimney repairs required.

Even if your chimney doesn’t require cleaning but you need an inspection, please note that there is still a service call charge for this service and we will at that time do a Safety Inspection of your chimney for this service call fee.

Schedule a chimney cleaning appointment with us today, and our experienced chimney sweeps will ensure your Zero Clearance Fireplace Unit is safe to use.

Cancelled appointments will be subject to a cancellation fee. Once you schedule the chimney cleaning, at that point you are authorizing the terms of the cancellation fee. Cancellation fee applies to people who cancel the chimney cleaning or call in to say they need to reschedule but are not actually rescheduling the appointment at that time. To not get the cancelation fee, you actually need to call up and physically reschedule the appointment time to another day/time. The charges do not apply to people who call in and actually reschedule the time.